Faultless reliability.

DISCO CONTOUR.

The CLAAS range of DISCO CONTOUR rear mowers provides suitable machines for all farms and agricultural businesses. This efficient all-rounder combines the outstanding performance of the MAX CUT mower bar with other DISCO advantages. The central suspension ensures perfect ground-contour following in all models. The 120° road transport position also makes the machine compact and safe on the road.

|

Optimum ground-contour following. Optimum ground-contour following.

The mower units in the CONTOUR model series are suspended at the centre of gravity, so they can pivot freely and adapt to the ground contours. The correct adjustment height is indicated by arrow markings on the arm.

|

Solid construction. Solid construction.

The construction of our machines is robust and clearly laid out, with mower components built for maximum strength and stamina. To protect the hydraulic components, they are integrated in the frame structure wherever possible.

|

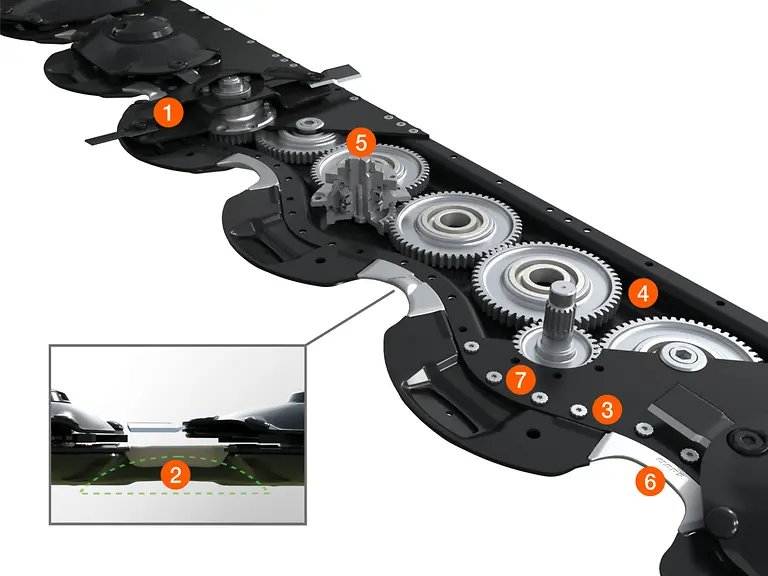

MAX CUT mower bar. MAX CUT mower bar.

Even the smallest can benefit from CLAAS professional-level technology. So the MAX CUT mower bar, with the same high-quality components as in the larger mowers, is also available for working widths from 7' 2" (2.20 m) – including permanent lubrication. Depending on the country, you can choose whether to have it with or without the quick knife change system.

|

Center of gravity suspension. Center of gravity suspension.

The large suspension spring acts on the middle of the machine frame. In addition, the line of force of the spring passes straight through the mower's center of gravity. The inner and outer support ensures that the force is transferred evenly to the mower bed.

The small spring additionally protects the mower bar drive. Our unique center of gravity suspension brings the advantages of central suspension to the side-suspended models.

|

Drive line. Drive line.

The mower is driven via especially low-maintenance PTO drive shafts that do not require a safety chain. The robust belt drive absorbs peak loads and is tensioned by means of a rotary knob without needing tools. From there the force is transferred to a double gearbox, which delivers the drive input from above straight to the first cutting disc for optimal crop flow.

|

Mechanical collision protection. Mechanical collision protection.

The overload protection responds immediately upon collision with an obstacle by swinging the mower unit up and back. Mowing can then continue after briefly reversing to reset the mower. An additional bracket also protects the outer edge of the mower from damage.

|

Attachment and removal. Attachment and removal.

As well as various hitching category options, the left lower link pin is in a slightly lower position for easy hitching. The built-in parking position for light plugs and hydraulic hoses, along with the pivoting drive shaft support, makes for more convenient handling. Hitching is very straightforward thanks to the KENNFIXX® grips on the hydraulic hoses.

|

105° transport position. 105° transport position.

The machine's center of gravity shifts even further to the middle, so that the tractor's rear wheels are as uniformly loaded as possible. The double gearbox allows for a narrow transport width and a clear view to the rear. A double floating piston ram allows the mower to be folded safely on slopes, with gentle braking before it reaches the end point.

|

Unrestricted access. Unrestricted access.

Both halves of the protective cover conveniently fold upwards to allow easy access for maintenance and cleaning. The outer edge of the cover, which is more prone to wear, can be replaced separately.

|

Space-saving. Space-saving.

A separate storage frame is available for space-saving storage. The mower can be transferred directly onto it from the tractor – with no additional supports required.

|

Added comfort. Added comfort.

An optional mechanical headland limiter is also available, which means that only one cable is required for both headland limiter and transport lock.

|

Swath formation. Swath formation.

An additional outer swathing disc for tidy swath formation is available for DISCO 100 mowers, as well as an inner disc or plate, depending on the model.

|

Perfect condition. Perfect condition.

The conditioner models in the DISCO 100 series are optimally configured and are of course equipped with the MAX CUT mower bar. The slightly lower left link pin ensures quick hitching and with the 95° transport position, they can travel safely behind the tractor from road to field. The built-in headland limiter is now supplied as standard in conditioner mowers. And with these models too, the speed can be reduced if conditions allow.

Conditioner mowers can significantly reduce the drying time of the mown crop. We offer the right conditioner to suit the crop, fitted either with tines or rollers.

|

MAX CUT.

MAX CUT. Suspension.

Suspension. Speed reduction.

Speed reduction. Tine conditioner.

Tine conditioner. Roller conditioner.

Roller conditioner.

Optimum ground-contour following.

Optimum ground-contour following. Solid construction.

Solid construction. MAX CUT mower bar.

MAX CUT mower bar. Center of gravity suspension.

Center of gravity suspension. Drive line.

Drive line. Mechanical collision protection.

Mechanical collision protection. Attachment and removal.

Attachment and removal. 105° transport position.

105° transport position. Unrestricted access.

Unrestricted access. Space-saving.

Space-saving. Added comfort.

Added comfort. Swath formation.

Swath formation. Perfect condition.

Perfect condition.